Your HMI design partners.

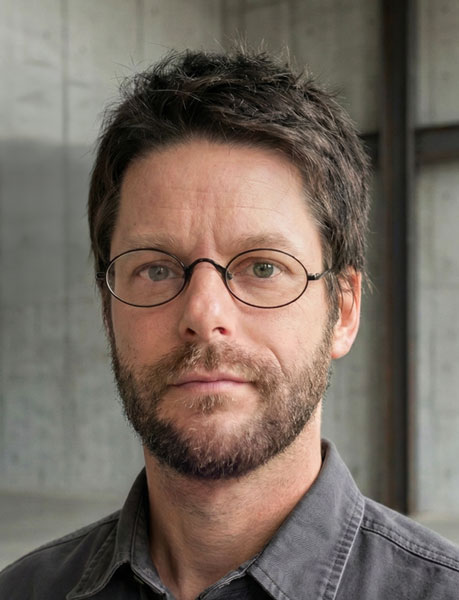

Petri Tanninen

With over 20 years of experience and patents in applied industrial monitoring interfaces, Petri specializes in translating complex control logic into defensible, high-performance HMI architectures. He holds an MDes from OCAD University.

Anna Dlubak

Anna combines a deep background in physical manufacturing processes with rigorous operator-experience design. She ensures that Industriant's digital HMI components are rooted in the physical realities and workflows of the plant floor.